Acrylic Candy Box_Making box process

Facebook

Twitter

Pinterest

LinkedIn

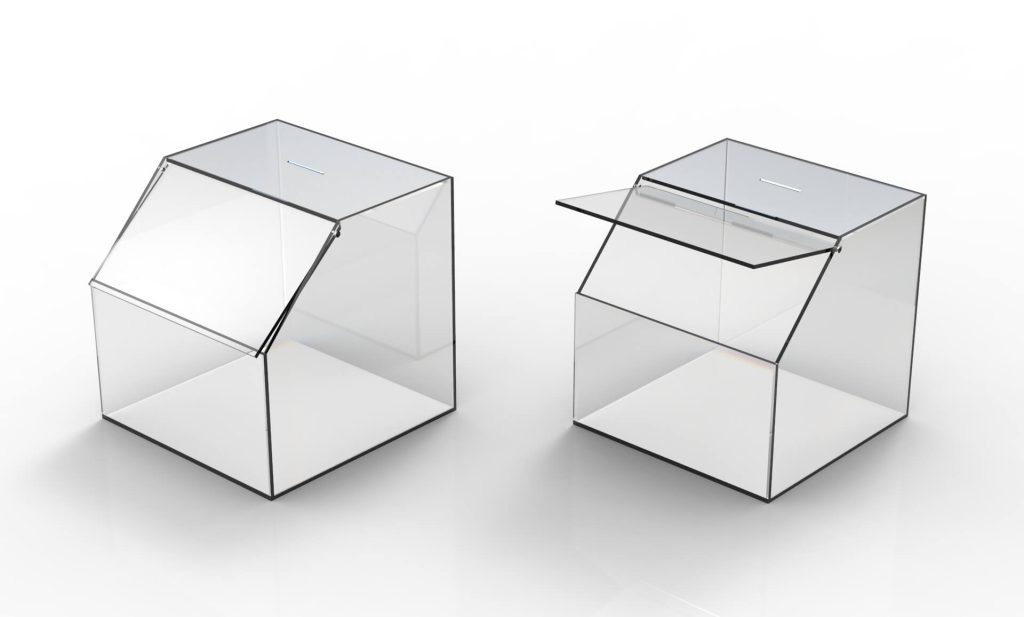

The manufacturing process of acrylic boxes typically involves the following steps:

- Design: The first step in manufacturing an acrylic box is designing the product. This includes selecting the appropriate dimensions, thickness, and shape of the box, as well as any additional features such as hinges or locks.

- Material selection: Next, the appropriate type of acrylic is selected. This can include different grades of acrylic, such as cast or extruded, depending on the desired properties of the box.

- Cutting: Once the material is selected, it is cut to the appropriate size and shape using specialized cutting tools such as a laser cutter or a saw.

- Forming: The acrylic pieces are then heated to a specific temperature and molded into the desired shape using a vacuum or pressure forming process.

- Assembly: After the pieces have been formed, they are assembled using adhesive bonding or mechanical fasteners such as screws or rivets.

- Finishing: Finally, the box is sanded and polished to achieve a smooth and uniform surface. This may involve using various polishing compounds and buffing wheels to achieve the desired finish.

We also design simple acrylic box for client, depend on your request.

Images print on back site or inside, before we glue acrylic sheet.show your photo or brand on acrylic display box.

Contact to us, we will make design and production according to your needed.

Tags:

Latest Post

Acrylic Display Rack with Stunning Metal Branding

August 1, 2019

No Comments

Classic acrylic 5 sides box

June 20, 2019

No Comments

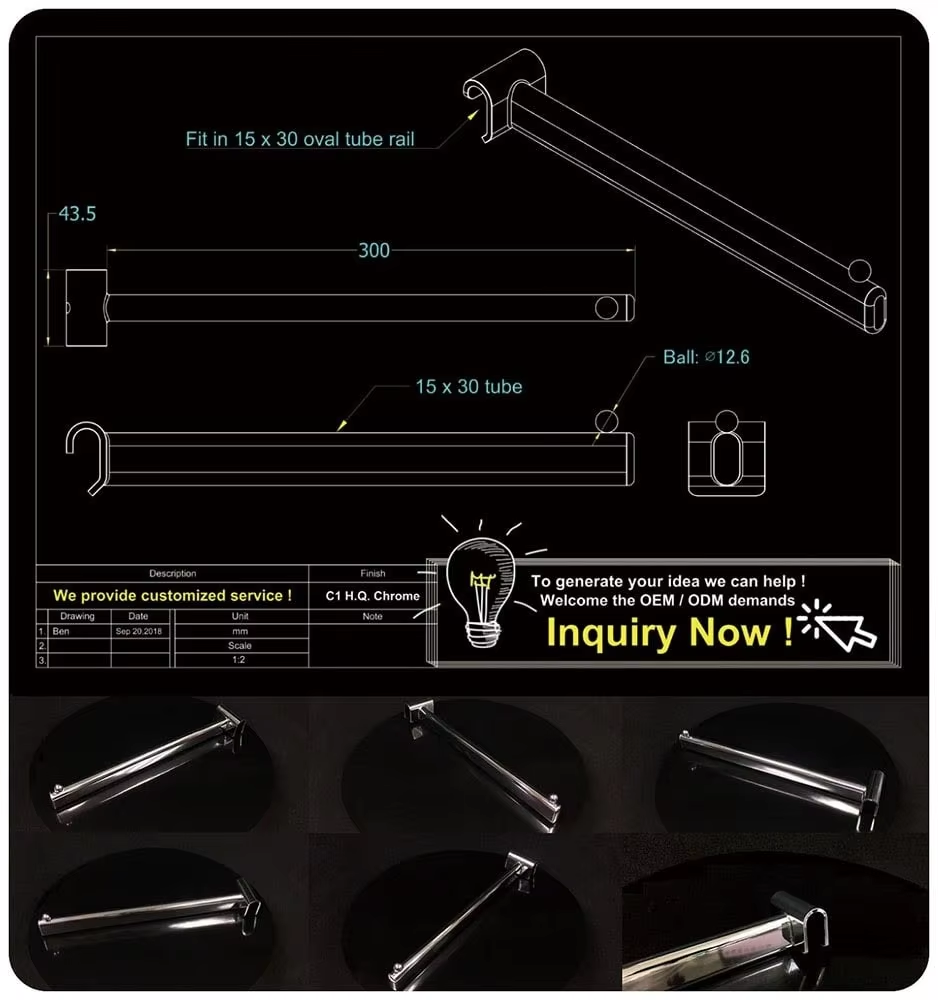

Shaper’s Display Hooks

June 18, 2019

No Comments